Tennis balls might look simple but they are the most complex balls that are being manufactured in the sports scene. They are designed and made based on the specifications given by the International Tennis Federation. And the complexity lies in the specifications like weight, size, rebound, hardness, etc.

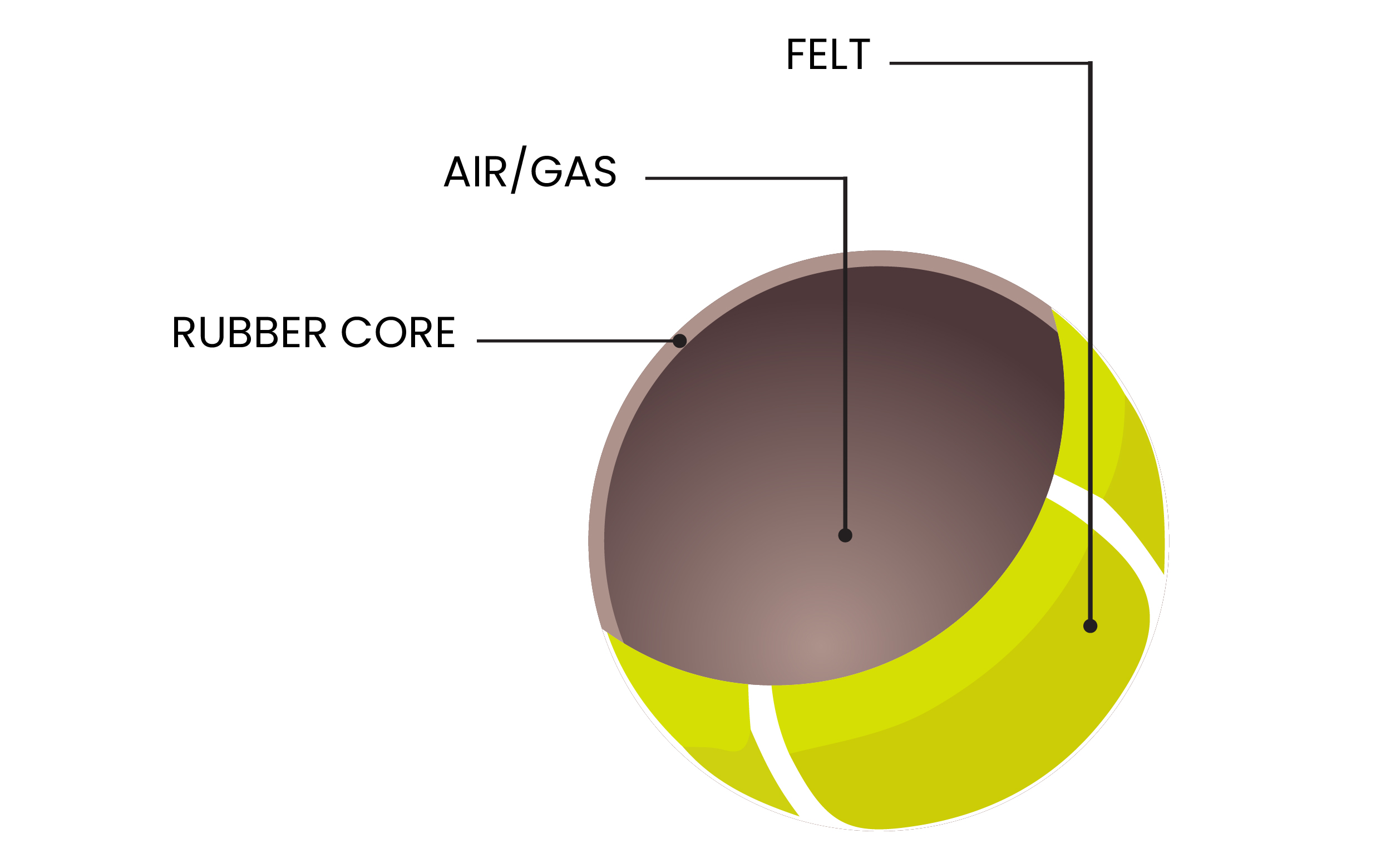

Tennis balls are made using rubber and felt. The rubber is molded into a ball by joining two pieces. This rubber ball is covered using felt. The ball is pumped with pressurized gas to achieve a certain amount of bounce.

Production:

The core of the tennis ball is made of rubber. This rubber that comes from the factory is carefully kneaded. This makes it soft and easy to work with. This rubber is mixed with different kinds of powders to give it strength, color, thickness, etc.

This rubber mixture is extruded through an orifice and cut into small pallets. These pallets are then pressed into hollow semi-shells.

These shells are then combined together to make a ball. These balls are pumped with pressurized gas. This gives them the desired bounce and stiffness.

This rubber ball is covered with felt. This felt is made of wool or synthetic material depending upon the required durability and spin.

The ball is then molded and heated to ensure better adhesion of the rubber and the felt.

The ball is then steamed so gives the felt a slight fluff making the ball softer.

Felt:

There are generally two types of felt that are used for manufacturing tennis balls:

- Melton Cloth: This material has high wool content and is used in premium balls in the market. The woven construction gives the ball extra softness and also offers consistency in the bounce and flight.

Ex: Dunlop Australian Open, Tecnifibre X-One, Wilson US Open, Head Tour

- Needle Cloth: This is a relatively cheaper material and has a high amount of synthetic fibers. These balls are usually economical and used for practice. They are made using the needle punch construction.

Ex: Wilson Championship, Babolat Championship

Rubber:

The formulation of the rubber that is used to make tennis balls, especially pressurized ones, is based on natural rubber. The performance or the quality of the ball depends on the percentage of natural rubber; the higher the percentage the better the quality of the ball.

After all, the process of production is complete and the name of the brand is printed on the ball. The pressurized balls are packaged in a pressurized tin that secures the pressure inside the ball. The non-pressurized balls are packaged in regular containers.

A tennis ball looks like nothing but a lot of design procedure goes behind its production. The specifications and the material used slightly differs based on the playing level. All this makes a tennis ball more complex than it appears to be.

Comments